Selective laser melting

Training needs

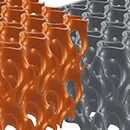

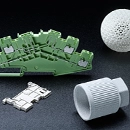

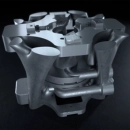

Selective laser melting (SLM) is one of the most interesting 3D printing processes for industry. Thanks to tool-free manufacturing directly from CAD data, it is possible to produce individual metal components within a very short time. Even weight-reducing cavities, integrated cooling channels or supporting honeycomb structures can be included in the design and easily implemented. This makes 3D objects generated by laser melting ideal for lightweight construction, for example in the automotive, aerospace or medical technology sectors.

- Basics (process principle, machines, process chain)

- SLM metals

- Data preparation and construction job layout

- Construction process (laser, powder application, exposure, post-process)

- Advantages of tool-free manufacturing

Training content

Learning goals

Our selective laser melting training offer shows you the relevant 3D printing technology basics and its advantages for industry. In addition to detailed information on the process principle and the process chain, you will learn everything you need to know about the materials used as well as correct data preparation and construction job layout.

Simply arrange a training date

If you are interested in our offer and in using 3D printing to optimize your production process, then feel free to contact us and make an appointment. We look forward to hearing from you.

Deutsch

Deutsch English

English Italiano

Italiano