To list

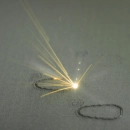

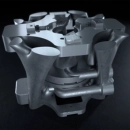

Selective laser melting (SLM)

3D objects are produced from metal powder using high-power laser beams. In contrast to selective laser sintering (SLS), the material to be processed is heated only slightly, if at all, and is melted at the specified points at laser temperatures of up to 1,250°C. A scraper then applies a new layer of powder to the build platform. In order to avoid undesirable effects such as deformation of the component or curling during manufacturing, the object is created on a support structure, which is firmly welded to the build base and must then be removed manually.

Deutsch

Deutsch English

English Italiano

Italiano