Copper inductors

PROTIQ makes the development of high-performance inductors easier than ever: in our free inductor configurator, you can precisely define your individual geometry - in just a few steps and without CAD knowledge. 3D printing with copper then enables complex structures with maximum electrical and thermal conductivity. This gives you compact, efficient inductors that are precisely tailored to your application - from the first prototype to series production.

Unique copper inductors from 3D printing

Try our free online configurator!

Induction heating with customized copper inductors

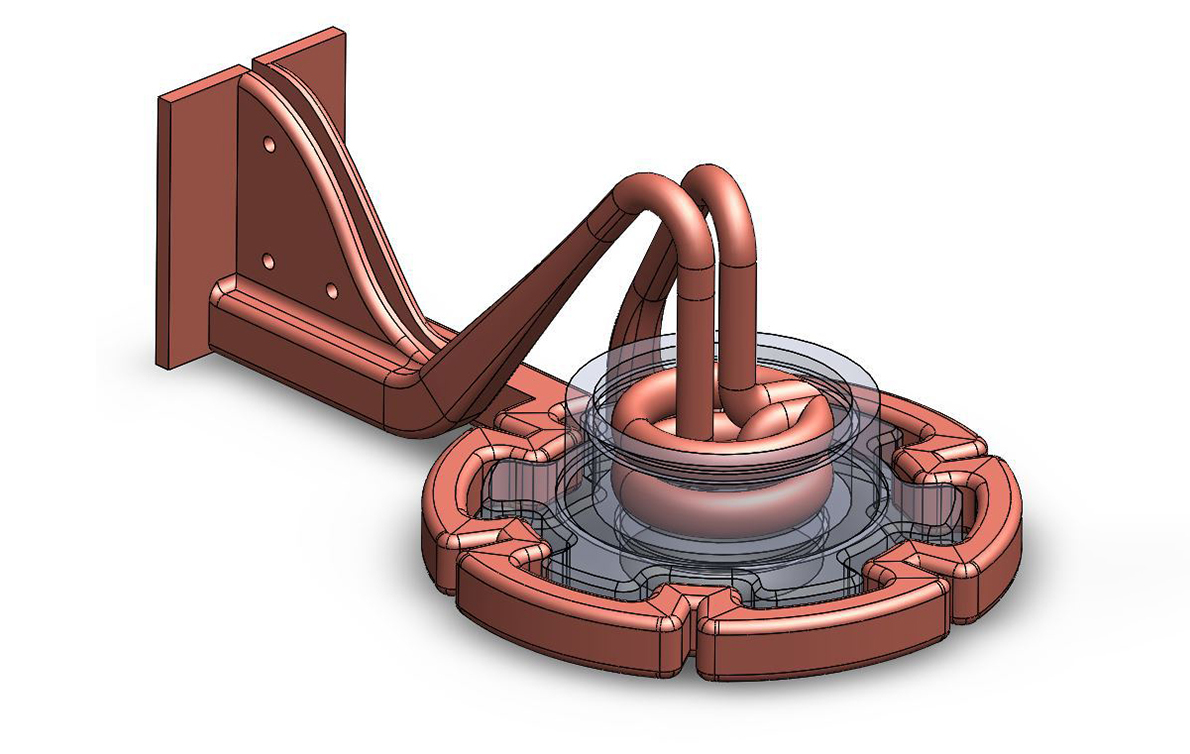

Induction heating requires precisely fitting copper inductors for processing different component shapes. Until now, these have mostly been produced by hand in complex processes. On the PROTIQ Marketplace, we produce your individual induction coils quickly and cost-effectively using 3D printing. As a result, you benefit from reduced delivery times, greater design freedom and a longer service life for the coils.

We are happy to manufacture your existing coil design according to the 3D CAD data provided. Simply upload the coil geometry using the upload button and order production in just a few steps. Simple coils for which you do not yet have 3D data can be easily created yourself using our innovative inductor configurator and ordered straight away. No CAD or design experience is required. For complex coil shapes that the configurator does not show, our CAD engineers will be happy to create a 3D model for you based on your technical drawing. Please ask for a quote.

What is induction heating?

Induction heating is a widely used industrial heating process. A workpiece made of electrically conductive material (e.g. steel or cast iron) is placed in the magnetic field of an induction coil - the inductor - and heated in a very short time. Strong alternating currents are used to generate the magnetic field, so that the coils are cooled from the inside with cooling water. For this reason, inductors are usually hollow. In contrast to processes in which heat is generated by an oven or a flame, induction heating generates the heat directly in the component. Compared to other methods, this results in a very efficient process and a high level of efficiency. Furthermore, the heating process can be very precisely controlled and reliably reproduced via the current intensity and the generator frequency. These factors have made induction heating the standard in many industrial applications.

Induction heating is a widely used standard for surface hardening of highly stressed components, such as transmission components in automobiles. Precise, localized heating followed by abrupt cooling increases the hardness and strength of the component surface. In induction brazing, two components are precisely heated and bonded with the help of a brazing material. The heat required for the joining process is generated by an inductor. Precise, homogeneous heating to the target temperature is crucial for the quality of the joint. Components that are given their geometry using hot forging must be heated before machining. A precise inductor offers the advantage that heating only takes place locally at the required points.

The inductor - the heart of induction heating

The shape of an inductor is directly related to the process accuracy, as the heat is only generated at the points where the electromagnetic eddy currents are induced in the workpiece. The more precisely the inductor is matched to the geometry of the component to be heated, the more precisely the heat distribution can be controlled. This is why an individually developed inductor is required for each design.

Why inductors from 3D printing?

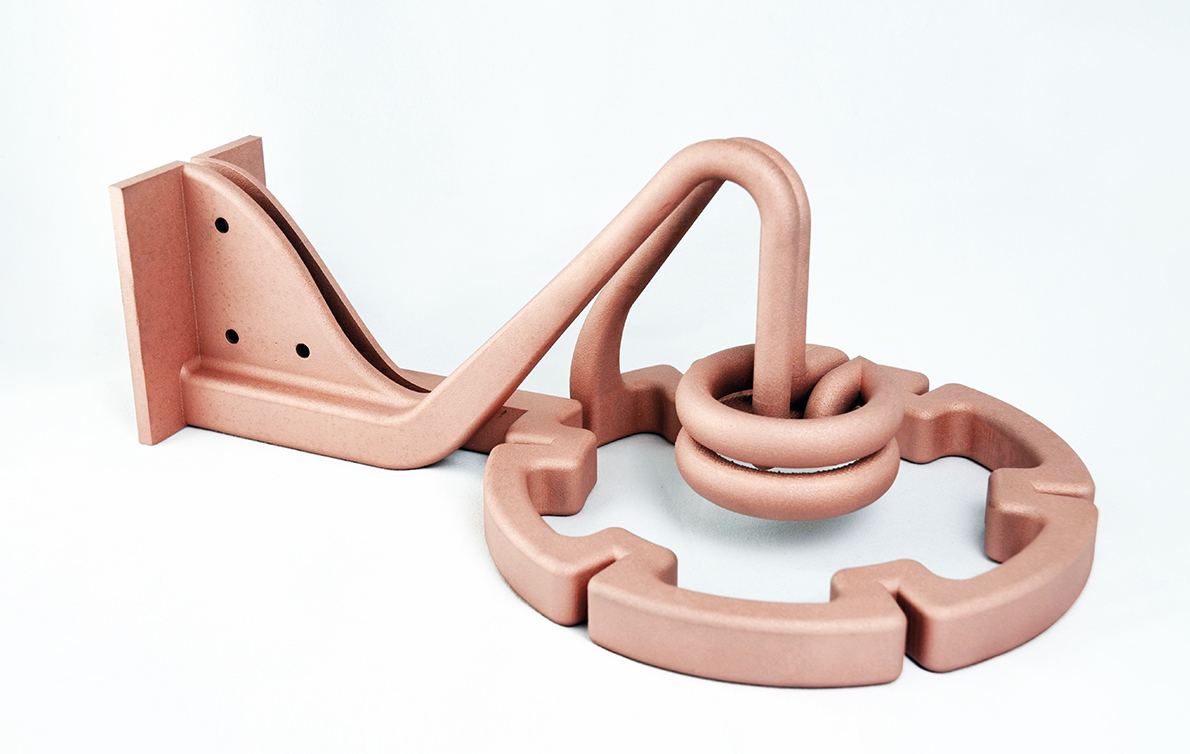

Traditionally, copper inductors are shaped by manual bending or soldering, which is why only relatively simple geometries can be produced. The manual production process is also very time-consuming. With frequently changing workpieces, companies have to accept correspondingly high costs for the purchase of new inductors. At the same time, the manually manufactured coils only have a low repeat accuracy due to the manual production process.

Alternatively, more complex inductors are CNC-milled from solid material. In order to create the required cooling channels, the individual components must then be joined by welding or soldering. This process is also time-consuming and cost-intensive. At the same time, these joints represent a weak point in later operation and a potential source of failures.

3D-printed inductors from PROTIQ offer many advantages

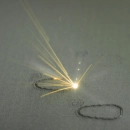

PROTIQ inductors are manufactured using the additive manufacturing process of selective laser melting. Metal components are created directly from CAD data and without the use of additional tools. This allows the coils to be manufactured automatically and directly in one piece. This eliminates the need for expensive manual production. The avoidance of soldered seams also ensures an increased service life and longer service life of the coils.

The result is highly conductive and durable inductors that correspond exactly to the specified dimensions - a level of precision that is virtually impossible to achieve using conventional methods. Thanks to additive manufacturing, even individual and complex geometries can be realized within a few days.

Inductors from PROTIQ - fast and digital order processing

In industrial 3D printing with copper, the time and costs involved in manufacturing a custom-made inductor can be effectively reduced. The end-to-end digital business process of the PROTIQ Marketplace saves valuable time during the ordering process. After uploading the inductor geometry, you can obtain an automatically generated quote and initiate the order in just a few clicks. If you do not yet have 3D data for the coil, you can use the inductor configurator to put it together quickly and intuitively according to your individual specifications. The configuration is based on the modular principle and takes into account the special requirements of industrial customers. Production can begin immediately after receipt of the order and you will receive the coils within a few days.

- Cost-effective production of individual geometries

- Increased design freedom

- Precise and true-to-data implementation

- Short delivery times thanks to tool-free production

- Longer service life of the coils

Advantages of inductors from 3D printing

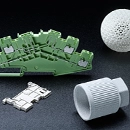

Configure inductors easily online

Induction heating is widely used in the metalworking industry. Automotive and industrial suppliers use this effective heating process to harden components, among other things. For efficient use, the induction coils have to be specially designed and produced for each area of application in a time-consuming process. It often takes weeks or even months from receipt of the order to completion of an inductor.

The inductor configurator in combination with tool-free production using 3D printing significantly shortens this lengthy process. Simply select the right basic shape for your application and determine individual parameters such as the number of windings, coil diameter or the position of the connection. There are six basic shapes to choose from, which you can adapt to your personal requirements with just a few clicks using the modular principle. You will receive your ready-to-use inductor just a few days after receiving your order, as production using industrial 3D printing can begin immediately!

Create application-specific inductors in four simple steps

Step 1: Select basic shape

Choose the optimum geometry for your requirements from six standard shapes for internal and external field inductors.

Step 3: Define connection element

Each inductor can optionally be fitted with a bracket. Determine the dimensions of the base plate individually.

Step 2: Configure inductor

Determine your desired dimensions based on height, cross-section and diameter. You can also specify the number of windings as well as the diameter and spacing of coils and ducts.

Step 4: Complete the order process

The price of your inductor configuration is automatically calculated for you online. Choose one of the many convenient online payment methods and take advantage of our worldwide delivery service.

Try out our free online configurator!

Advantages of the inductor configurator

- New, individual design options

- Economical production thanks to the modular principle and additive manufacturing

- Intuitive handling of the user interface

- Delivery within a few days of receipt of the order

- Guaranteed printability of 3D models

Copper in 3D printing - a challenge

Your inductor is manufactured in 3D printing using selective laser melting. As copper almost completely reflects the radiation from conventional laser melting systems, many 3D printing service providers use alloys with a comparatively low copper content. However, the conductivity of components made from such alloys is often unsatisfactory. PROTIQ has succeeded in developing a unique process with which highly conductive copper can be additively processed. Our process enables us to produce components in complex geometries, which significantly expands the possibilities of inductor designs. We offer our customers the opportunity to develop and implement individual designs to meet their specific requirements.

Find out more about 3D printing with copper here:

Special shapes and simulation-based optimization

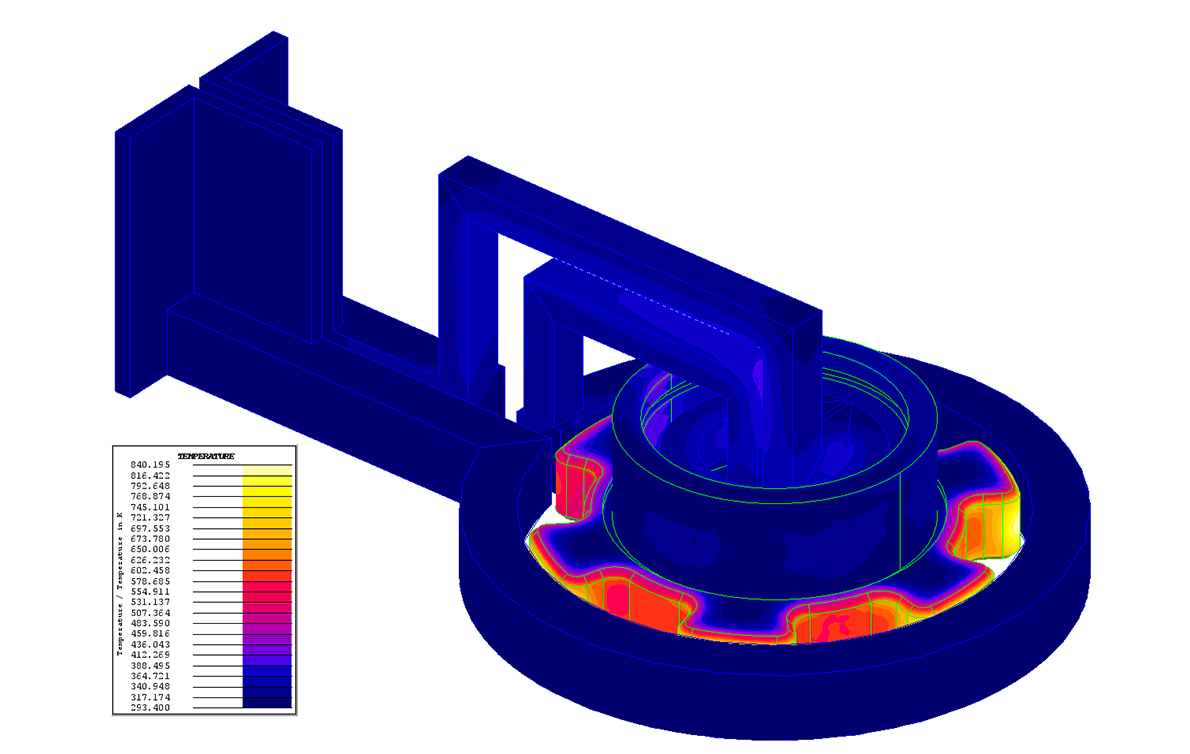

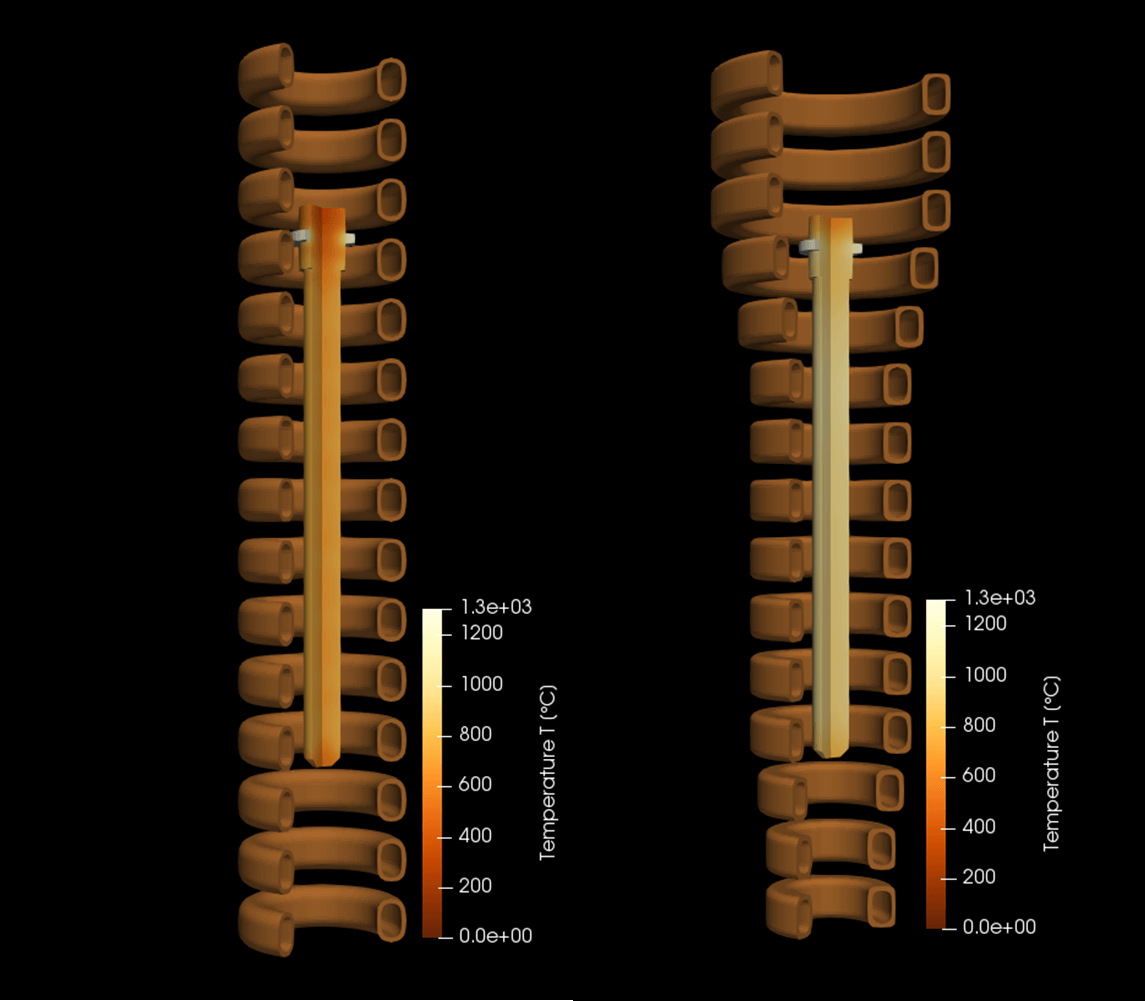

The heating behavior of inductors is crucial for the efficiency of your processes. However, in conventional manufacturing processes, many test geometries usually have to be produced and tested in real heating trials before the optimum coil can be found. This is costly and time-consuming. With a computer-aided simulation of your processes, you get the ideal inductor for your application.

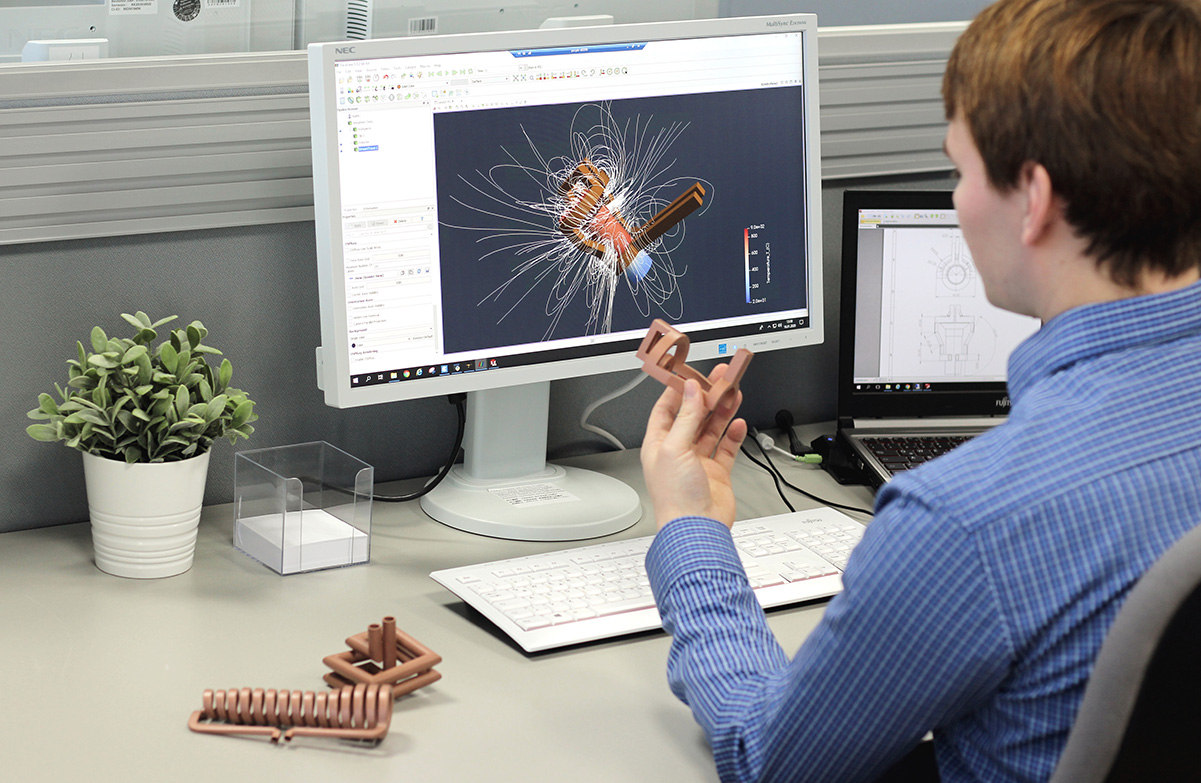

With simulation methods to the perfect inductor

Using numerical simulation methods, the behaviour of the coils in the process can be visualized and an optimized inductor geometry can be determined. The components are then produced quickly and cost-effectively using a 3D printing process from electrically highly conductive pure copper.

You gain valuable insight into otherwise invisible process influences and their interactions. This information about the heating process can be used directly for the development and improvement of new processes.

The optimized inductors additively manufactured by PROTIQ impress with their fast and precise heating behaviour. This allows more precise hardening patterns to be set on the component and shorter cycle times to be achieved in series production.

How does the simulation and optimization of the inductors work?

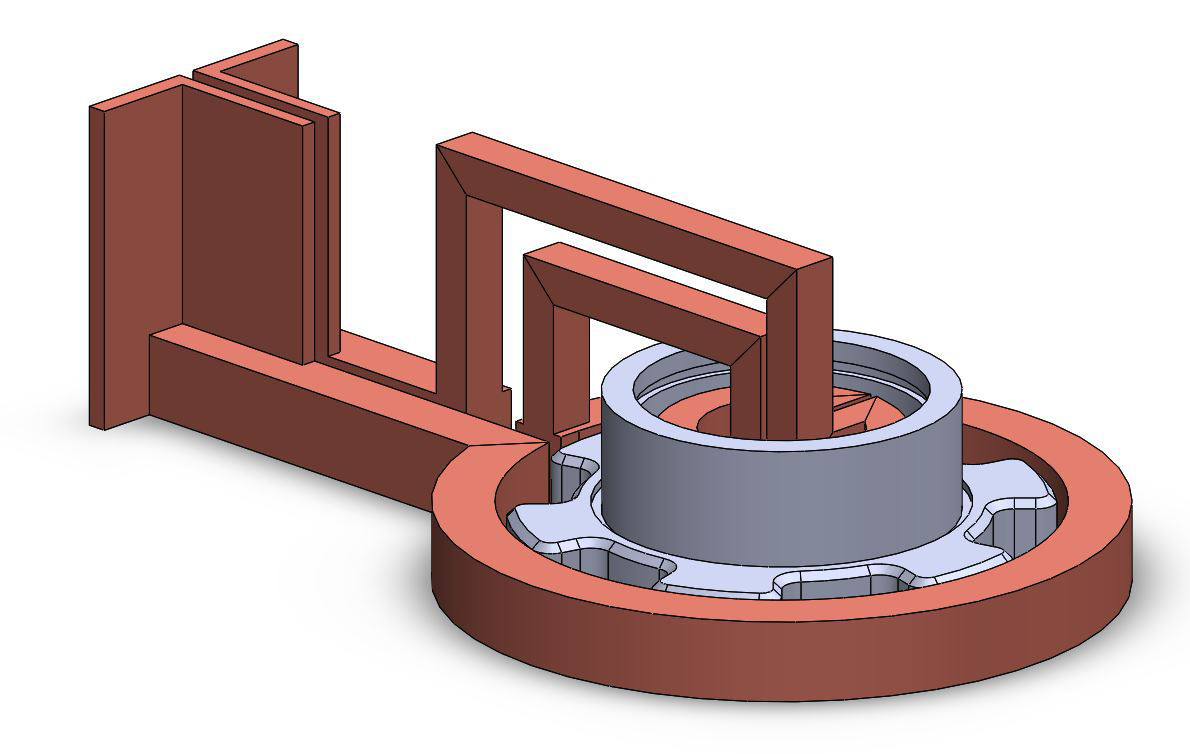

In the first step, the inductive heating process of your application is mapped in a simulation model. In addition to the geometry of the inductor and the component to be heated, information about the existing boundary conditions and process parameters is also stored in this model. On this basis, the thermal heating behavior of the component and the electromagnetic properties of the coil can then be mapped and investigated.

The results obtained enable a much more detailed analysis of the process behavior than real heating tests. As part of the simulation, for example, the heating inside the component can also be examined or the magnetic field that builds up can be visualized. In this way, PROTIQ analyses and optimizes existing inductors or determines the parameters for new heating processes.

This gives you high-quality copper coils that are ideally suited to your applications. We would be happy to provide you with an individual offer!

How to benefit from simulation and 3D printing:

- Valuable analyses of the process behavior

- Visualization and evaluation of the simulation reveals potential for optimization

- Coils with ideal properties for your individual processes

- Time savings during development

- Reduced development costs

- Fewer real tests with test geometries required

- High-precision inductors, 3D-printed from pure copper

- Production of your induction coils within a few days

Advantages of additive manufacturing for your processes

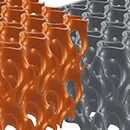

3D printing has long since established itself as a manufacturing process for induction coils. The advantages over conventional production methods are numerous: by using computer-aided numerical simulations, expensive tests and valuable development time can be significantly reduced. Additive manufacturing can also be used to easily produce very complex geometries where other manufacturing processes reach their limits. Individual profile shapes and minimal bending radii are no obstacle, meaning that innovative inductor geometries with optimized magnetic field guidance and improved process properties can be developed. Production using 3D printing takes just a few days and PROTIQ uses 100% pure copper.

Free download

In our free brochure on copper inductors in 3D printing, you can find out all about additive manufacturing with copper, inductive heating, our inductor configurator and the simulation-based optimization of inductor geometries.

Why copper in 3D printing?

Copper has extremely high electrical and thermal conductivity. 3D printing allows complex geometries to be produced without solder joints, which significantly increases the efficiency and service life of the inductors. PROTIQ uses a specially developed process to reliably print pure copper with a copper content of up to 99%.

Can I replace existing inductors with 3D printing?

Yes, existing inductors can be replaced by digitized replicas. The advantage lies in tool-free production and the possibility of optimizing the geometry - for better energy efficiency or a longer service life, for example.

How long does a 3D-printed copper inductor last in industrial use?

Thanks to the homogeneous structure without soldered joints and the high conductivity of the material, the inductors are durable and resistant. The service life is comparable to or even longer than that of conventionally manufactured coils.

Can I also have cooled inductors printed?

Yes, 3D printing allows cooling channels to be integrated directly into the geometry. This improves heat dissipation and enables more compact designs with higher performance.

Deutsch

Deutsch English

English