PolyJet/MultiJet Modeling

The PolyJet process

In PolyJet or MultiJet Modeling (PJM/MJM), liquid acrylic polymers are layered onto a build platform with a printhead with one or more nozzles and cured by exposure to UV lamps. The printhead moves across the platform in paths pre-defined by a CAD model during the process until a layer is completely printed.

The UV lamps are located directly on the printhead and cure the plastic as soon as it has been applied. The intensity of the UV light is adjusted so that the uppermost layer does not cure completely, which achieves a stable connection between the superimposed layers. Once the last level has been printed, the UV lamps travel over the entire component several times to complete curing.

Advantages

- Very large variety of materials (from solid to rubbery)

- Transparent components

- Composite materials producible

- High precision and surface quality

- Fast process, since no heating and cooling times are needed

- Production of 3D-printed plastic injection molding cavities

- Good finishing possibilities

PolyJet/MultiJet Modeling in the application

Due to the high dimensional stability and material durability of the produced components, 3D printing using the PolyJet or MultiJet process is regarded as a high-end solution in the field of additive manufacturing processes. In addition, the method stands out because of the large variety of materials that can be efficiently integrated into a single object. While PolyJet Modeling applies substances layer by layer across multiple printheads, in MultiJet modeling different materials can be processed simultaneously in one printing.

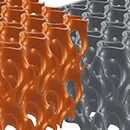

Combine different materials in one production step

These benefits pay off in many ways. For example, the interplay of colored and transparent materials allows the internal structures of components to be presented in a particularly illustrative manner. It is also possible to combine materials with different characteristics, so that, for example, parts made of solid plastic can be combined with a soft rubber coating. Finally, there is even the possibility to create new composite materials with hybrid properties by bringing together substances with different physical properties in a specific manner. Desired degrees of hardness or colorations can be exactly defined with a suitable mixing ratio.

Technical information

- Wall thicknesses from 0.2 mm

- Layer thickness 16 μm and 32 μm

- Components up to 342 mm x 342 mm x 200 mm can be produced in one piece

- Tolerances: +/- 0.5%, min. 0.05 mm

Limitations

- Lower temperature resistance

- Materials slightly brittle

- Materials not UV-resistant (embrittlement and discoloration possible)

- Restrictions in the geometric freedom, since support material must be removable with water jet (accessibility, risk of damage)

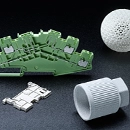

Precise concept- and functional models

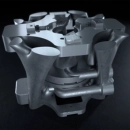

The result of the PolyJet or MultiJet process are functional components that impress with their high level of detail resolution and surface quality. Complex geometries with small wall thicknesses and exact contour sharpness can be produced from a wide range of materials. The created objects are ideally suited as conceptual models, since they convey the aesthetics and functionality of the final product in a particularly realistic way. They score points in numerous sectors, including electrical engineering, vehicle construction, medical technology, architecture, and the consumer goods sector, where filigree models are used, such as in jewelry design or toy development.

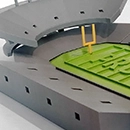

Optimize processes and shorten time-to-market

Thanks to the exact geometries, designers can put their developments to the test in a realistic manner and identify potential errors or weak points at an early stage. This means a significant increase in efficiency for the product development process and shorter times to market launch (time-to-market). Another popular field of application, where time savings also play a decisive role, is the efficient production of master models for geometrically accurate molding. Thanks to the smooth surface structures and the high dimensional stability, the molds produced in the PolyJet or MultiJet process are immediately ready for use in downstream processes such as vacuum casting.

Deutsch

Deutsch English

English Italiano

Italiano