Industrial 3D printing optimizes tool and mold making

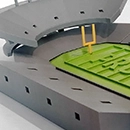

For many companies, manufacturing injection molding or shaping dies is one of the most expensive, time-consuming steps in the production process. Despite ultra-precise tooling machines, established ablative or shaping processes often reach their limits when it comes to complex geometries. Additive manufacturing offers new opportunities to optimize tool making processes while increasing tool productivity significantly.

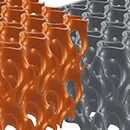

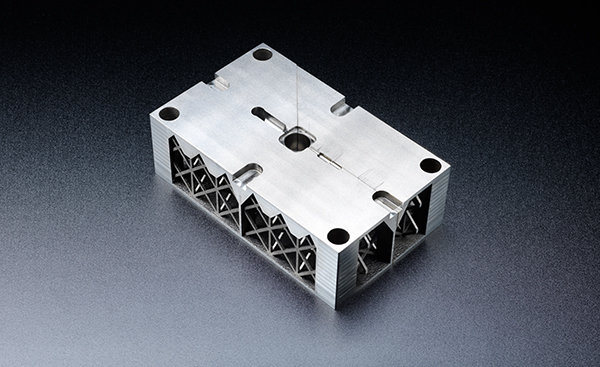

Conventional tool making uses ablative and shaping production process, such as milling, turning or drilling. These are associated with various process-related restrictions in implementation, made clear by the following practical example: Hot stamping or injection molding requires tools with integrated cooling channels. A coolant is passed through these channels to help quickly and evenly dissipate heat. Until now, these types of channels were simply drilled into the tool, something that could physically only be done in a straight line. With more demanding geometries, this makes it virtually impossible to place cooling channels evenly and near the surface of the workpiece.

Improved functionality thanks to 3D printing

Since complex shapes inside the workpiece cannot be implemented adequately using ablative or shaping methods, potentials for improvement are often left untapped. Here is where one of the greatest advantages of additive manufacturing comes into play: 3D printing creates objects made of shapeless base materials using CAD data. The layered structure does not require additional tools and enables the integration of complicated geometries based fully on the functionality and design of the component.

Optimized tool geometry improves heat dissipation, cutting cycle times for injection molding by one-third on average. Thanks to less warping, the quality of the injection-molded parts is increased significantly.

Tools from industrial 3D printing

- enable even heat dissipation

- reduce cycle times

- increase quality of injection-molded parts

.jpg)

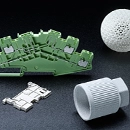

Industrial 3D printing on the PROTIQ Marketplace

All you need to produce your 3D object is a printable CAD model of your workpiece. On the PROTIQ Marketplace, production can begin as soon as your order is received. You receive your 3D-printed part for tool making just days after placing your order.

To ensure the necessary surface quality for injection-molding tools, all external surfaces of your 3D model should have an offset of 0.7 to 1 mm. Following production, all components are conventionally finished and trimmed to size. Industrial 3D printing not only creates new objects, but in some cases can also repair damaged tools. If you'd like to learn more about how you can optimize your production processes with additive manufacturing, contact us!

3D printing – advantages for tool making

- Save money for the long term: Shorter cycle times and improved part quality lower the unit price for series products

- Discover new possibilities: Design-based construction increases innovative potential

- Fast production: Production of your 3D workpiece begins as soon as your order is received

Deutsch

Deutsch English

English Italiano

Italiano