3D printing in the automotive industry

3D printing has made enormous progress in recent years and is increasingly being used in the automotive industry. The use of 3D printing is particularly interesting, for example, in the production of spare parts for classic cars, which are often difficult or impossible to obtain - or in the development of electric cars, where prototypes and small series need to be produced quickly and flexibly.Additive manufacturing in the automotive industry - key technology for the mobility of the future

The automotive industry is undergoing profound change. E-mobility, autonomous driving and the focus on sustainability are presenting manufacturers with new challenges. At the same time, modern production technologies are opening up completely new possibilities. One of these key technologies is 3D printing.

Whether in the development of electric vehicles, the production of individual components or the manufacture of spare parts for rare models - 3D printing has long been more than just a trend. It is a decisive factor for the mobility of the future.

Why 3D printing in the automotive industry?

- Speed: prototypes are created in just a few days instead of several weeks.

- Flexibility: Changes to the design can be implemented immediately, without additional tooling costs.

- Cost savings: No high investments in molds or tools for small series.

- Availability: Spare parts and individual components can be produced at any time - regardless of stock levels or supply chains.

Where is 3D printing used in the automotive industry?

Prototyping - speed in development

In the past, prototypes were produced using processes such as injection molding or CNC milling. This meant long waiting times, high tool costs and limited flexibility for design changes. A simple component could take weeks and cost several thousand euros. With 3D printing, such parts can now be produced in just a few days. Changes to the design can be implemented immediately without having to produce new tools. Development cycles are drastically shortened and costs are significantly reduced.

Small batch production - flexibility without expensive tools

Traditionally, the production of small quantities was extremely expensive, as special tools and molds had to be made for each series. These investments were only worthwhile for large production quantities. With 3D printing, small series for special models or test series can be produced economically. The technology enables individual adaptations to be implemented quickly and significantly reduces production costs, as no additional tools are required.

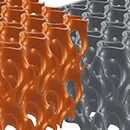

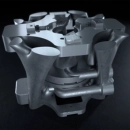

Lightweight construction - complex structures instead of solid components

Conventional processes such as casting or milling reach their limits with complex lightweight constructions. In order to save weight, several parts often had to be combined, which increased assembly effort and costs. With 3D printing, filigree structures and cavities can be integrated directly. This reduces weight by up to 50 percent, increases the range of electric vehicles and improves energy efficiency.

Electric cars - innovation for the mobility of the future

The development of electric vehicles presents manufacturers with special challenges. Range, weight and efficiency are decisive factors that determine the success of a model. Conventional production methods such as casting or milling quickly reach their limits here, as they often involve cumbersome components and long production times.

3D printing offers a solution to these requirements. Additive manufacturing can be used to produce lightweight yet stable components that reduce the overall weight of the vehicle and increase its range. Complex structures such as cooling channels for batteries or integrated attachment points can be realized directly in a component, which increases efficiency and reduces assembly costs.

In addition, 3D printing enables the rapid development of prototypes for new electric vehicles. Changes to the design can be implemented immediately without the need to adapt expensive tools or produce new ones. This significantly shortens the development time and accelerates the market launch of innovative models.

With attention to detail and respect for the past

Owning a classic car is a joy for many, even though, or perhaps because, something constantly needs to be repaired and restored. To preserve the feeling of the past, you want to keep the original as it was decades ago. This poses a challenge if there are hardly any originals left on the spare parts market or if they fetch particularly high prices. With the help of additive manufacturing, this no longer has to be a problem.

One of the biggest advantages of 3D printing for classic car owners is the ability to have spare parts manufactured quickly, precisely and true to the original. In the past, it often took a long time to find original spare parts. This sometimes involved long journeys and even higher costs. Thanks to 3D printing, spare parts can be produced quickly and cheaply, without long waiting times.

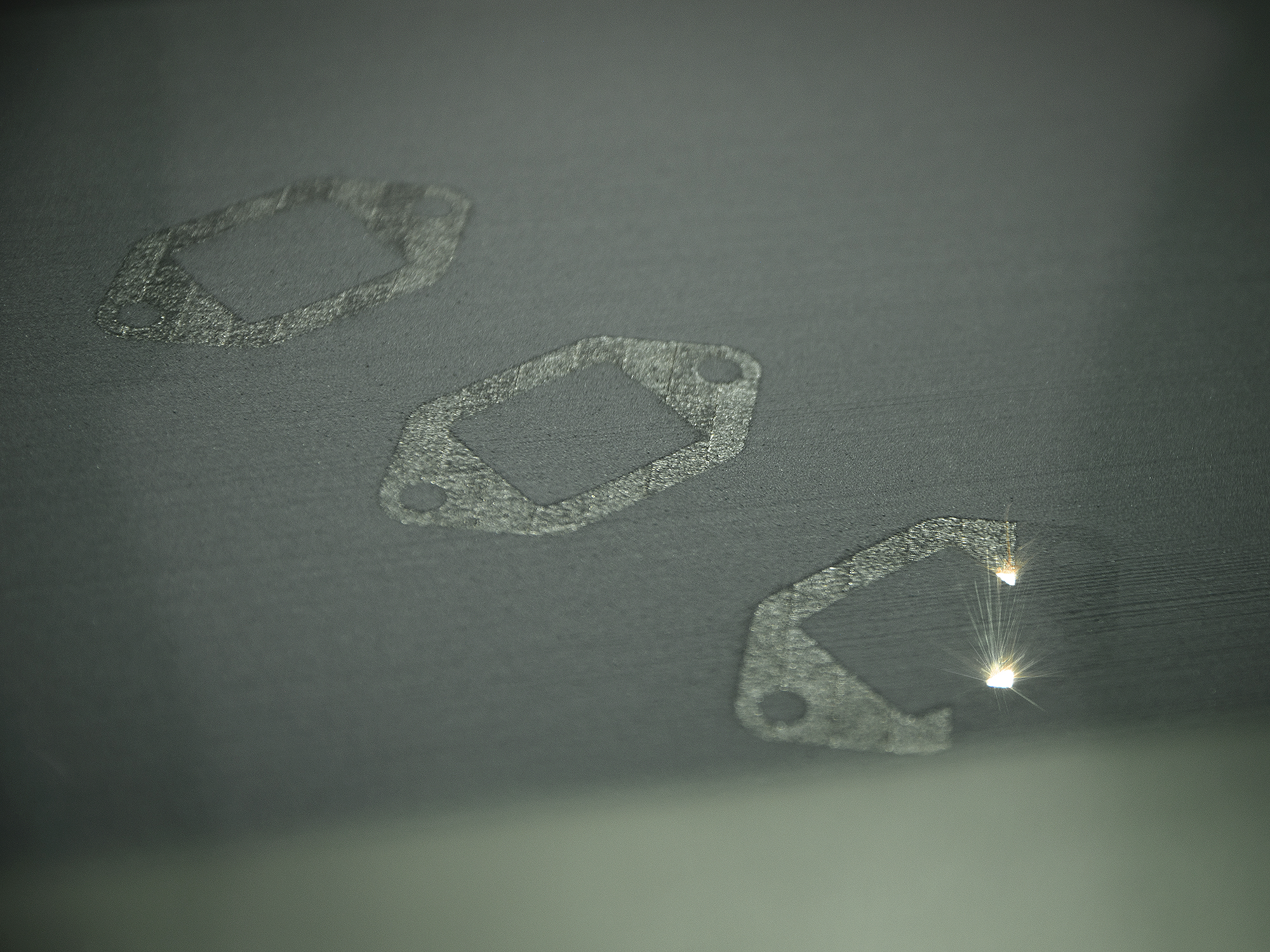

Additive manufacturing makes it possible to produce the required components directly from 3D data. This data can either be created using a 3D scan or generated by an engineer on the computer in a CAD design.

In addition to a faithful reproduction of the original component, highly individual adaptations can also be made. For example, special exhaust systems can be printed that are perfectly tailored to the needs of the vehicle. There are also many possibilities when designing interior parts or body details.

The most important facts about the production of classic car spare parts

- 3D printing enables the production of spare parts for classic cars that are difficult or impossible to obtain

- Use of 3D scanning technology enables accurate digital copies of original parts, which can then be precisely reproduced

- Faster production compared to making spare parts by hand

- Ability to produce parts with improved materials and features without significantly altering the original design

- Inductive adjustments possible directly in the 3D file

- Improved availability of spare parts and thus preservation of classic cars

- Production of spare parts for discontinued models can be resumed (small series)

The right material for your spare parts

3D-printed components made using the manufacturing process of selective laser sintering (SLS) for plastic components and selective laser melting (SLM) for metal components are particularly suitable as spare parts. The objects are created layer by layer by melting a fine powder with a powerful laser to form a solid component. The components are very stable thanks to the melting process and the material used and are also suitable for long-term use. Plastics can be painted or colored as desired. Metal components can be given an additional surface finish, such as coating, vibratory grinding or polishing.

Do you need a rare spare part for your classic car quickly? We manufacture using 3D printing and deliver it within a few days. We are also happy to support you with 3D data creation using a 3D scan or as part of a design service. Generate a free quote online now!

Metal materials for the SLM process

- MS1 (1.2709)

- PH1 (1.4540)

- 316L (1.4404)

- AlSi10Mg

- RS copper

- Pure copper

Areas of application

Whether bicycles, cars or tractors, we manufacture your individual spare part, true to the original in the style of the past or with personalized modification requests. An example application could be old plastic parts where the original plastic has already broken and become brittle. However, stable metal components for higher loads can also be produced using the additive manufacturing processes available at PROTIQ.

Application examples

- Covers, seals

- Trim strips, trim parts

- Air intakes

- Radiator figures

- Gear knobs

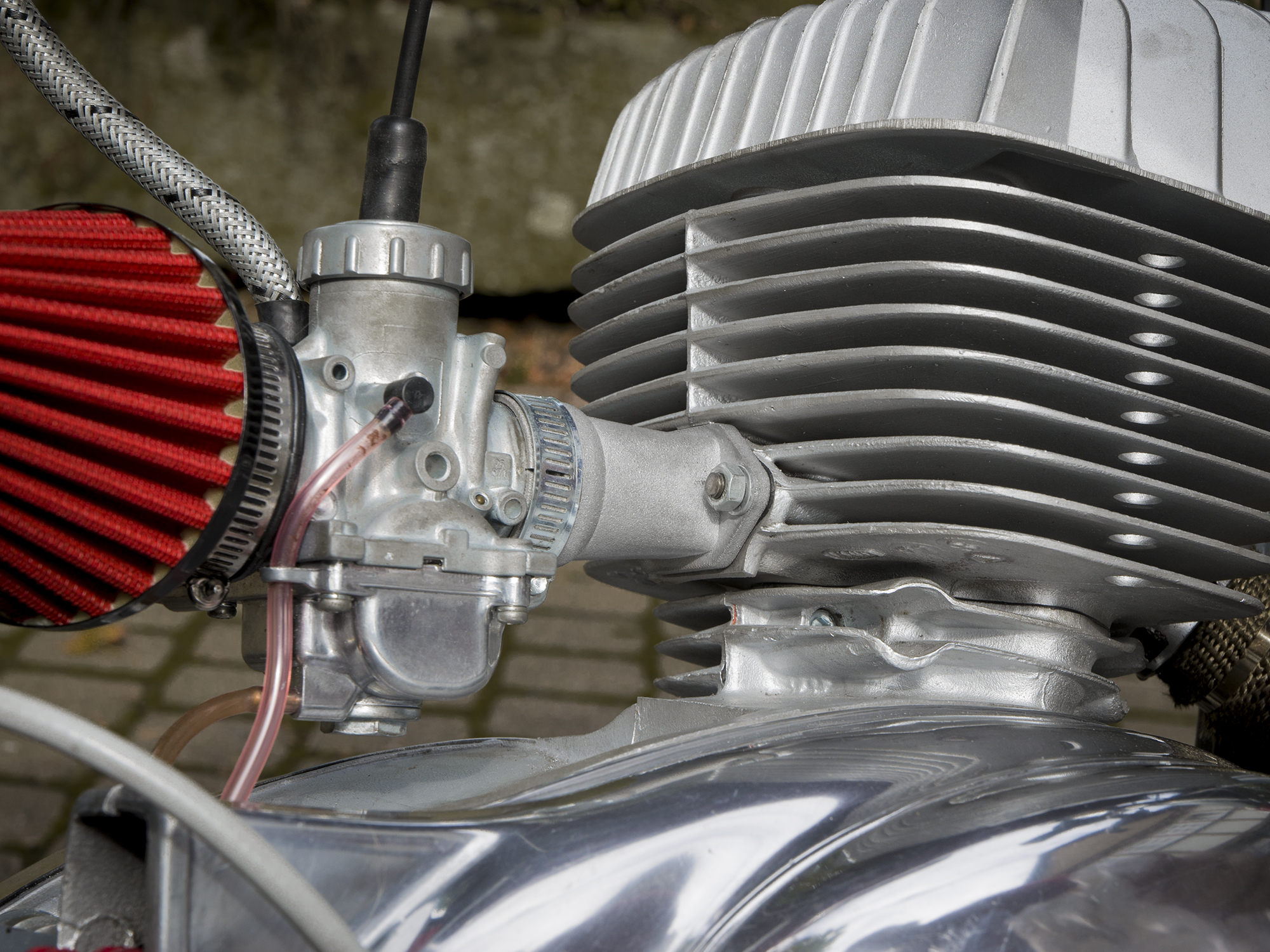

- Carburetor, intake funnel

- Filler plugs

- Dashboards

- Controls, knobs, handles

- Brackets

Difficulties and restrictions

Produce exact copies of aged original parts

It can be difficult to manufacture spare parts in such a way that they do not stand out among the decades-old original parts. In many cases, this problem can be solved by choosing the right material and any post-processing steps.

Legal restrictions

In some countries, there may be laws and regulations that restrict or prohibit the 3D printing of spare parts for classic cars. For example, additively manufactured components may not be used in some load-bearing and safety-relevant areas. Please find out in advance whether the spare part you require may be used for its intended purpose.

As with all additive projects, the general design guidelines also apply to spare parts for classic cars.

> Read more about the design guidelines here

Deutsch

Deutsch English

English Italiano

Italiano

.jpg)