Multi Jet Fusion

The process

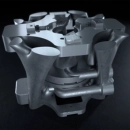

Multi Jet Fusion (MJF) is a new powder-based 3D printing process that produces high-resolution and precise 3D objects with low porosity and high surface quality. In contrast to selective laser sintering (SLS), MJF completely dispenses with the use of a laser beam. An inkjet print head prints components by applying two different binder fluids to the surface of the powder bed.

Infrared light instead of laser radiation

MJF uses infrared lamps as an energy source; the lamps continuously illuminate the printing surface. The powder particles to be fused are wetted by the print head with a heat-conducting fluid (fusion agent). The particles absorb the heat of the lamps and fuse together as well as with the underlying layer. In order to prevent the powder particles from fusing with each other beyond the intended area, a heat-inhibiting fluid (detailing agent) is simultaneously applied around the contours of the component. This ensures that the surface of the 3D object will be uniform and smooth.

Advantages

- High construction speed

- Process produces high density and low porosity components

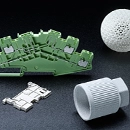

- Ideal for the fast production of prototypes with functional and mechanical properties

- Full-colour component manufacturing possible

Materials

Polyamide (PA) plastics are materials that feature long-term stability and resistance to mechanical stress. They are also highly resistant to many chemicals and are available in nearly all colors. We can produce impermeable objects on request. In addition to unfilled plastics, PROTIQ also uses filled, soft and hightemperature plastics.

PA12 (PA2200)

Characteristics

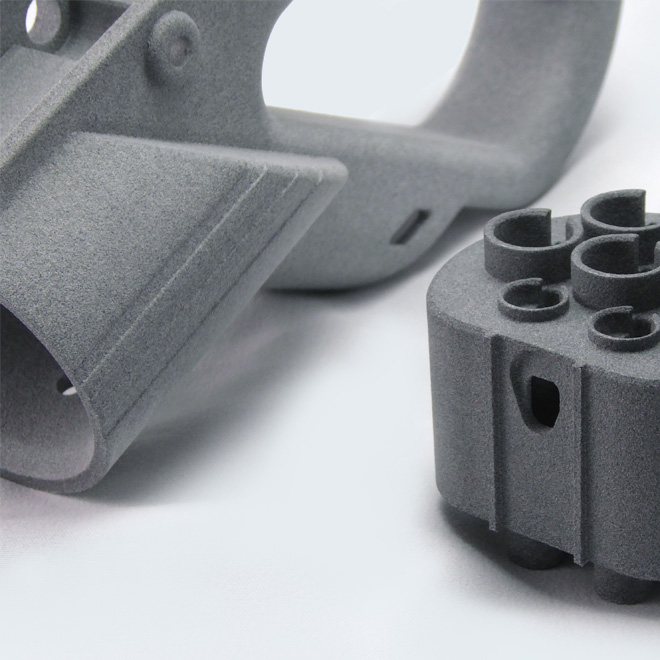

The fine powder is based on polyamide 12 and is often used as a substitute material for injection molding materials and fully functional components. A slightly rough surface is a characteristic of PA2200 objects.

| Base color | white |

| Price | |

| Precision | |

| Stability | |

| Flexibility | |

| Surface | |

| Feel | rough, light |

Innovation in white

In the past, it was not possible to process white material in the Multi Jet Fusion (MJF) process - until now. The new systems from HP significantly expand the application possibilities of MJF printing, as they can now also be used to produce white components, which are optically favoured in many industries. This represents a valuable expansion, particularly for prototyping and the production of finished parts.

White PA12 in the Multi Jet Fusion process combines the well-known advantages of the material, such as long durability and high flexibility, with the new colour option. White base material can now also be dyed and painted in bright colours, making it increasingly important in a wide range of applications.

To the article: "Innovation at PROTIQ: Multi Jet Fusion with white PA12" >

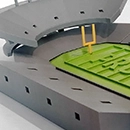

Multi Jet Fusion in the application

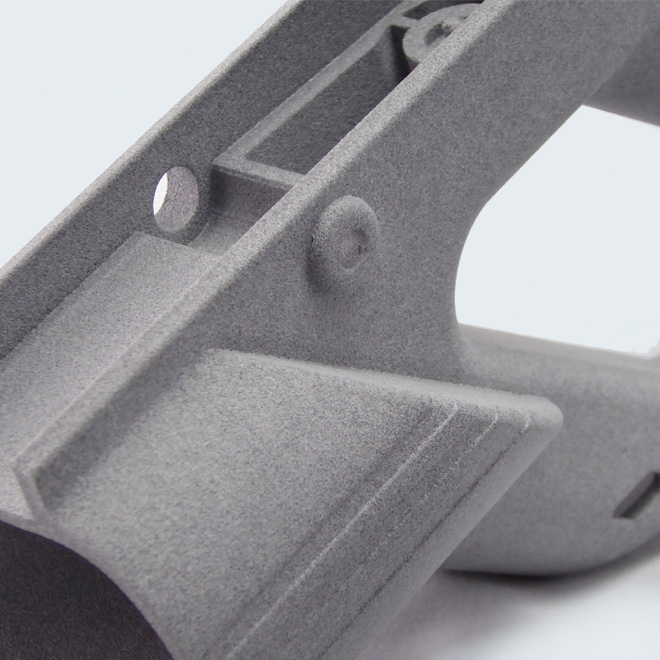

Producing functional and mechanically resilient prototypes with extremely short processing time – that is the great strength of Multi Jet Fusion technology (MJF). A construction speed of up to three centimeters of object height per hour makes it one of the fastest in 3D printing processes. For additive manufacturing, the record-breaking construction time is a trend-setting advance, as machine time is still one of the main price factors in production.

Produce more economically thanks to shorter lead time

In order to reduce the manufacturing time of 3D objects and the associated unit costs, components are often manufactured with increased layer thickness – a cost-cutting measure that has a negative impact on surface quality. After all, the rule is: the thicker the individual layers are printed, the more pronounced the step effect becomes. Thanks to faster printing processes and the resulting shorter machine times, Multi Jet Fusion can even produce very fine layer thicknesses economically. This allows the production of high-resolution prototypes and functional small series at a comparatively low unit price.

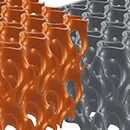

High-resolution and extra stable 3D objects

In addition to the significant time savings, the Multi Jet Fusion process also impresses with outstanding component quality: with 1,200 dpi, the systems achieve a resolution on the XY axis that can be used to produce objects at the injection molding level. Up to 30 million drops of binder fluid are applied to the entire work area per second. Since the fusion agent completely penetrates the object, the individual layers fuse together particularly homogeneously. This provides the final 3D objects with a uniform stability that is largely independent of the construction direction.

Technical information

- Wall thicknesses from 1 mm

- Layer thickness 70–100 μm

- Solid-colored components

- Components up to 400 mm x 300 mm x 400 mm

- Tolerances: +/- 0.7%, min. 0.1 mm

Limitations

- Slightly rough surface (due to powder grain size)

- Medium detail picture

3D objects made of temperature resistant plastic

The high-quality thermoplastic PA 12 is a suitable material for the new 3D printing process. It is temperature resistant and has excellent mechanical properties, making it a popular material for additive manufacturing. Further materials for the still young 3D printing process are already in the works: thanks to its open platform system, a large variety of materials will be available for Multi Jet Fusion in the future.

Coloured Multi Jet Fusion components

Components manufactured using the Multi Jet Fusion process can generally be coloured. However, there are a few details to consider:

Grey components: Components manufactured using the Multi Jet Fusion process are grey as standard. Subsequent colouring processes can be used to refine the surface. However, the colours are not bright and may appear slightly muted. The choice of colours is also limited; very bright and gaudy colours are not possible. The components can be coloured black particularly well.

Grey parts dip coated (produced by STURM INDUSTRIES)

Grey parts dip coated (produced by STURM INDUSTRIES)

White components: White components can also be printed with the new 3D printers in the HP Jet Fusion W series. The white components can also be coloured in bright or vibrant colours, comparable with components from selective laser sintering, for example.

Full-colour printing: The Multi Jet Fusion process makes it possible to produce full-colour components. The full-colour process offers a very wide variety of designs and a fast throughput time, eliminating the need for downstream colouring steps. It is also possible to produce the components directly with different colour layers, which can be used as an indicator for abrasion, for example. The disadvantage of this method is the more cost-intensive production compared to single-colour printing.

Full-colour printing (photo: Protowerk4D GmbH)

Full-colour printing (photo: Protowerk4D GmbH)

Deutsch

Deutsch English

English Italiano

Italiano